- ClientDSM

- Date2020/On-going

- RoleDemolition Consultant and CDM Advisor

- TeamStephen McCann – Mick Daynes – Yazan Osaily

We worked for DSM on the Eggborough power station, which was situated on the River Aire, between the towns of Knottingley and Snaith, deriving its name from the nearby village of Eggborough.

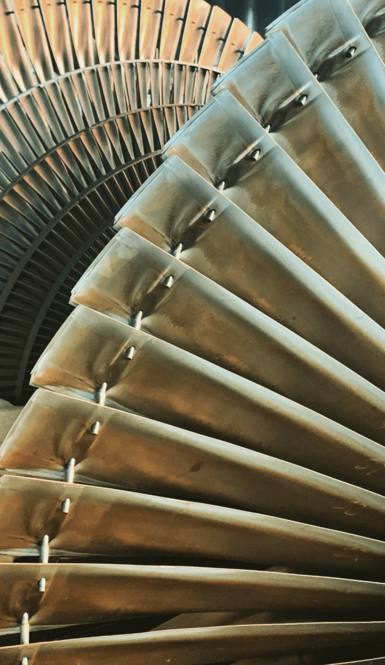

This project involves the decommissioning of the former 2-gigawatt coal-fired power station (comprising four 500-megawatt units, eight 90-metre high cooling towers and a 200-metre chimney), which was operational until March 2018. The decommissioning process started in 2018, starting with the coal conveyors being removed. The structural makeup consists of heavily reinforced concrete floors and foundations with heavy steel frames and cladding.

The demolition methods were a mixture of piecemeal method, hot-work preparation, explosives event, and progressive fragmentation using a demolition rig from a safe working distance, and clearing and processing the demolition arising materials.

As with all power stations, Eggborough brought about many challenges, such as temporary works coordination, structural instability during engineered preparation, time constraints as well as environmental controls.

Initially, PERSES was appointed as Safety Auditors conducting monthly safety audits on-site to ensure the health and safety standards were met, the CDM duties were complied with, and most importantly, the overall safety of the site and the workforce were maintained.

PERSES then developed bespoke training programmes for the burners and carried out skills gap analysis assessments for the operatives to ensure the level of training was as accurate and as specific to the task as possible.

Afterwards, PERSES was approached by the DSM and was appointed as the Demolition Consultants for the following phases of the project, which comprised the explosive demolition of the bunker bays and the demolition of the turbine hall. We initially started by checking the temporary works procedures and carrying out refresher training for all temporary works appointees. We also were engaged with the design team for the development of the method statements, which we also reviewed and commented on before the implementation. During the implementation phase, our role was to ensure compliance with the latest approved version of the method statements by conducting a health and safety process audit

- Carry out monthly health and safety audits and issue a report.

- Carry out skills assessments of the operatives.

- Deliver training to the site team.

- Carry out the demolition process site audit and issue a report

- Check the temporary works procedures.

- Carry out refresher training for all temporary works appointees.

- Engage with the design team for the development of the method statements.

- Review and comment on the complete method statements before implementation.

- Monthly health and safety process audits.

- Attend site meetings.

Need some health and safety advice?

Book a free no-obligation consultation with one of our Health & Safety consultants today

Pricing Plans

Pricing Plans